It takes about 30 minutes to innstall equipment generally

- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

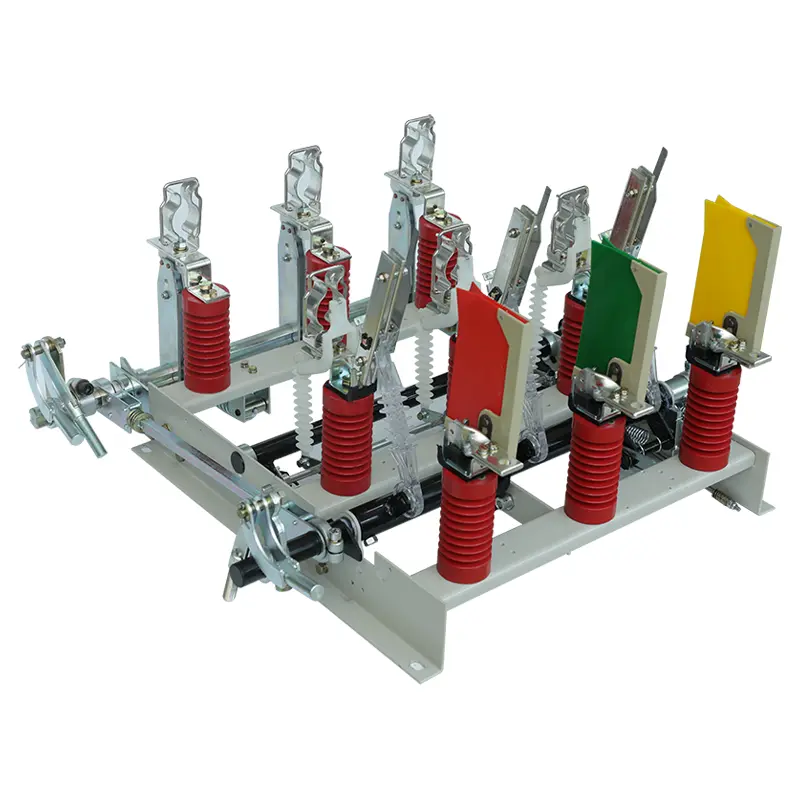

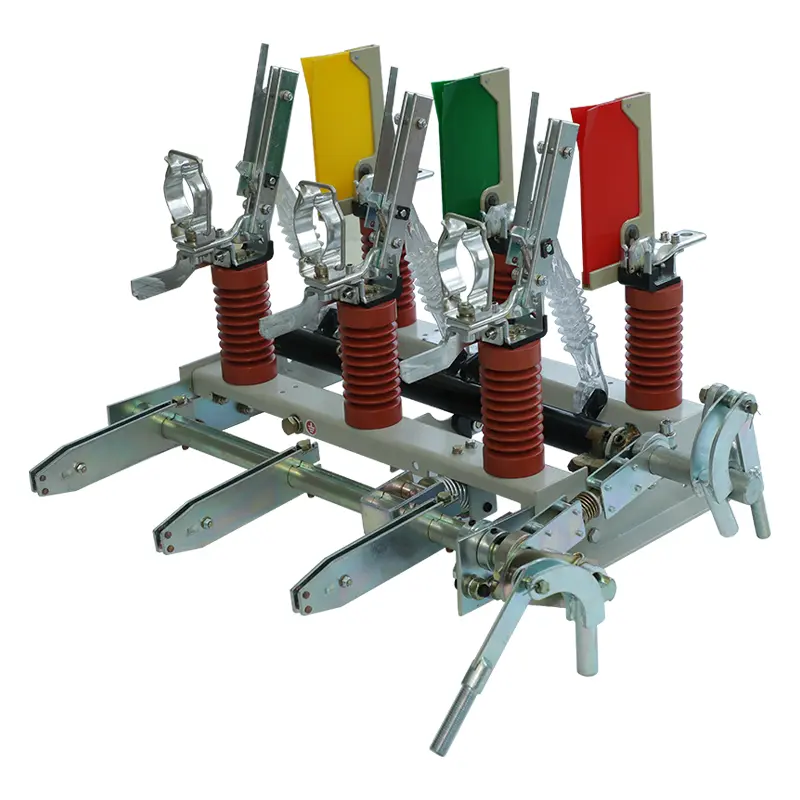

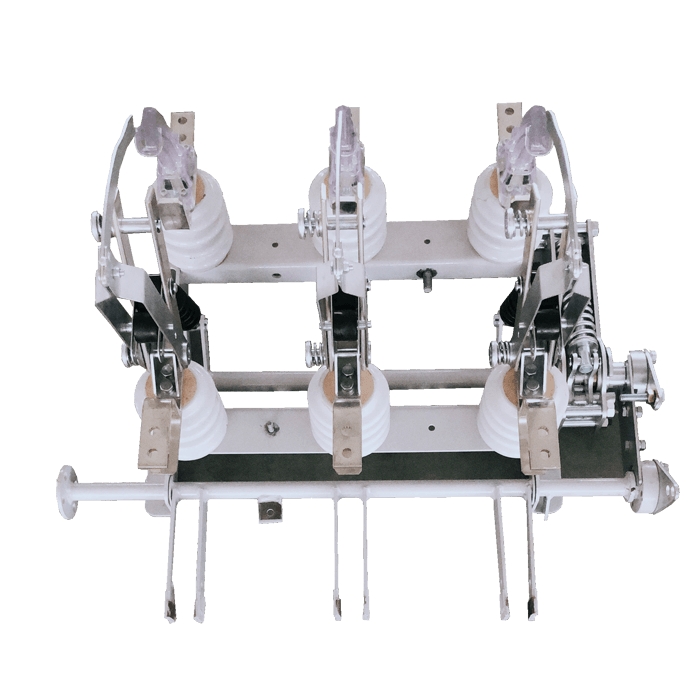

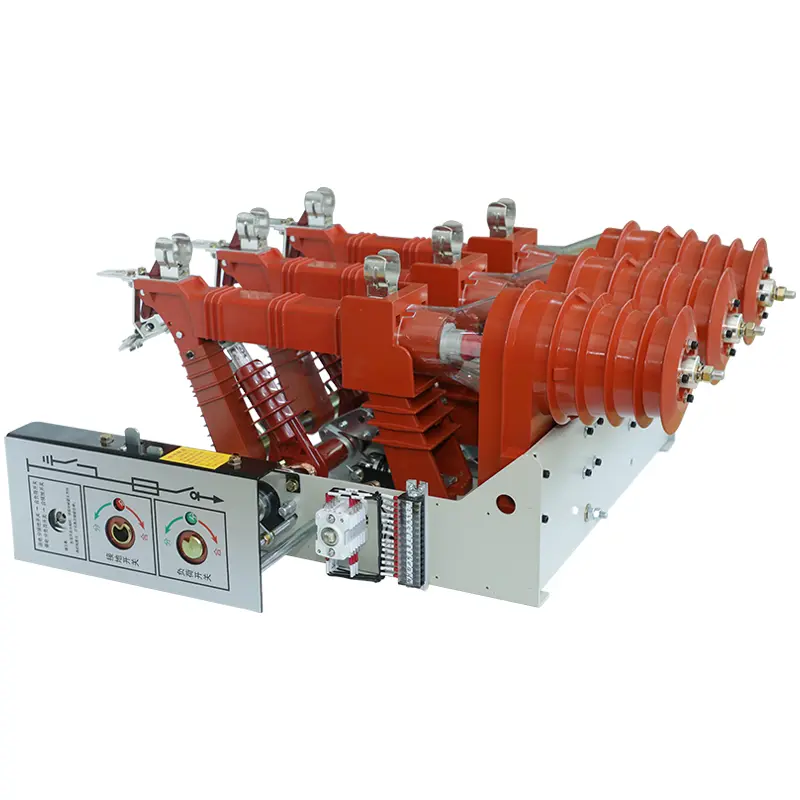

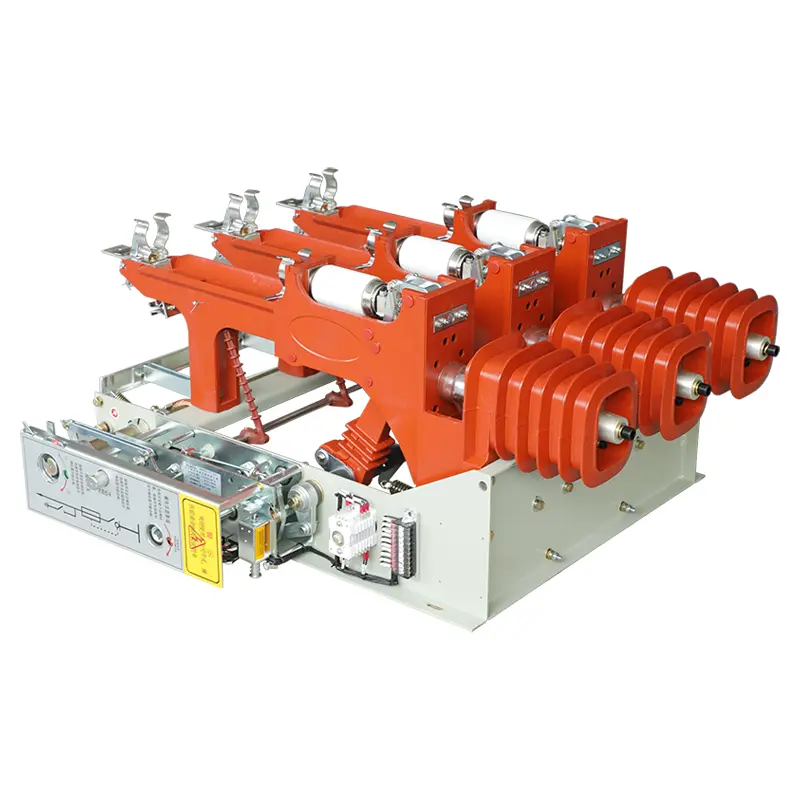

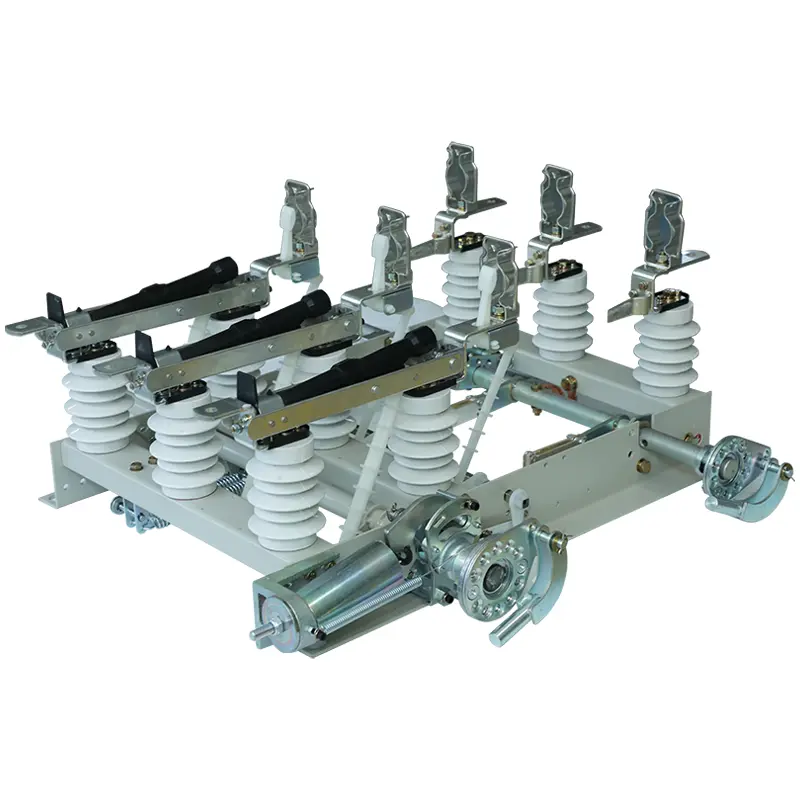

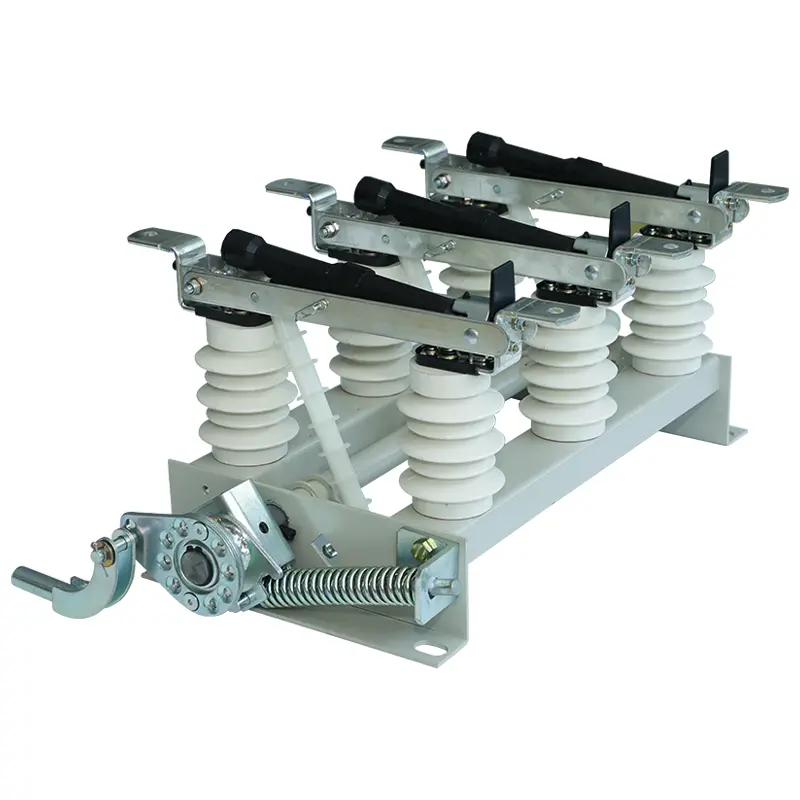

Indoor Vacuum Load Switch

Send Inquiry

SanGao high quality Indoor Vacuum Load Switch is equipped with a vacuum arc extinguishing chamber, which can quickly and thoroughly extinguish the arc, minimize contact corrosion, and ensure a longer service life. The company strictly follows the ISO9001:2008 quality management system, ISO14001 environmental management system, and OHSMS18001 occupational health and safety management system. Through continuous improvement and technological progress, Three Highs Electric has achieved rapid development and won a good reputation in the industry.

Main Features

The space saving structure is very suitable for indoor installation, and modular components can be easily integrated into various types of switchgear.

The Indoor Vacuum Load Switch is made of epoxy resin and advanced insulation materials, which have excellent dielectric strength and environmental resistance.

The rated lifespan is up to 10000 mechanical operations and thousands of full load switch operations, ensuring long-term stable performance.

Integrated mechanical interlocking and optional fuse protection to prevent misoperation and ensure operator safety.

Technical advantages

Indoor Vacuum Load Switch is capable of breaking rated current under normal and overload conditions and is suitable for frequent operation.

No gas emissions or oil consumption; Maintenance free vacuum chambers contribute to the construction of green and clean energy infrastructure.

Rapid disconnection and connection time can improve system stability and reduce thermal and electromagnetic stress in the power grid.

The vacuum contact system does not require re oiling, oil change, or internal cleaning, thereby reducing operating costs.

Application scenarios

Indoor Vacuum Load Switch is used for ring main unit (RMU) and switchgear in residential and commercial power supply networks.

Very suitable for protecting mechanical equipment and production lines in manufacturing factories and processing industries.

Indoor Vacuum Load Switch supports the grid connection of solar and wind power plants through reliable switching and load management.

Applied in applications such as subways, railways, airports, and data centers where compactness and safety are crucial.

Fully compliant with GB, IEC, and ANSI standards

Strictly follow the ISO9001:2008 quality management system for production

Obtained ISO14001 environmental certification

Controlled by OHSAS18001 Occupational Safety Management System

Company Profile

San Gao Electric is located in Liushi, the famous electrical capital of China, and is a symbol of innovation and resilience. The company covers an area of 10 acres and has a modern factory building of 10000 square meters. It has now developed into a vibrant enterprise with over 120 employees, including 20 experienced engineers and technicians. The registered capital of the company is 81.68 million RMB, with total assets of approximately 200 million RMB, equipped with advanced manufacturing and testing equipment.

FAQ

-

QHow many days you need to install the equipment?

-

QCan the equipment be installed under hot weather?

The installation environment for outdoor switches is around 40 degrees Celsius

-

QCan Your products be installed under the cold weather?

The installation environment for outdoor switches is around minus 35 degrees Celsius.

-

QCan I only buy some spare parts from you?

Yes,the MOQ is 50 units.

-

QWill you will attend the fair to show your products?

Yes,we will provide advance notice on our official website

-

QHow long it takes you to provide the designing options for us?

It depend on the complexity of the project.

-

QHow do you pack the equipment?

We use export-compliant wooden crates to pack the equipment

-

QCan you can design the equipment according to our size?

Yes,we will meet customer's requirments ASAP.

-

QDo you have any real project pictures of the equipment?

Yes,we uploaded in About US and also we will send you when you need.

-

QDo you have detailed and professional installation manual?

Yes,we will send them when customers need.

-

QIf OEM is acceptable?

We can offer OEM and ODM service.

-

QWhat is your term of payment?

Delivery upon receipt of payment.

-

QAre you a trading company or a manufacturer?

Yes,we are the professional manufacturer with 30years

-

QHow long is your delivery time?

Lead time depends on order quantity.Usually in 3-5days before shipping.